A single undetected spark can cost millions – or worse, lives.

- Container fires are becoming more frequent and severe.

- Battery-powered and misdeclared items increase the danger.

- Larger ships amplify the risk – a single ship carries thousands of containers – each a potential ignition source.

- Fires are often detected too late to contain effectively.

- As safety risks increase and regulations grow more complex, the demand for smarter, digital fire safety solutions is rapidly increasing across the industry.

- A new approach to fire detection for containers is required – and now, that new approach is here – the Temperature Monitoring System (TMS)

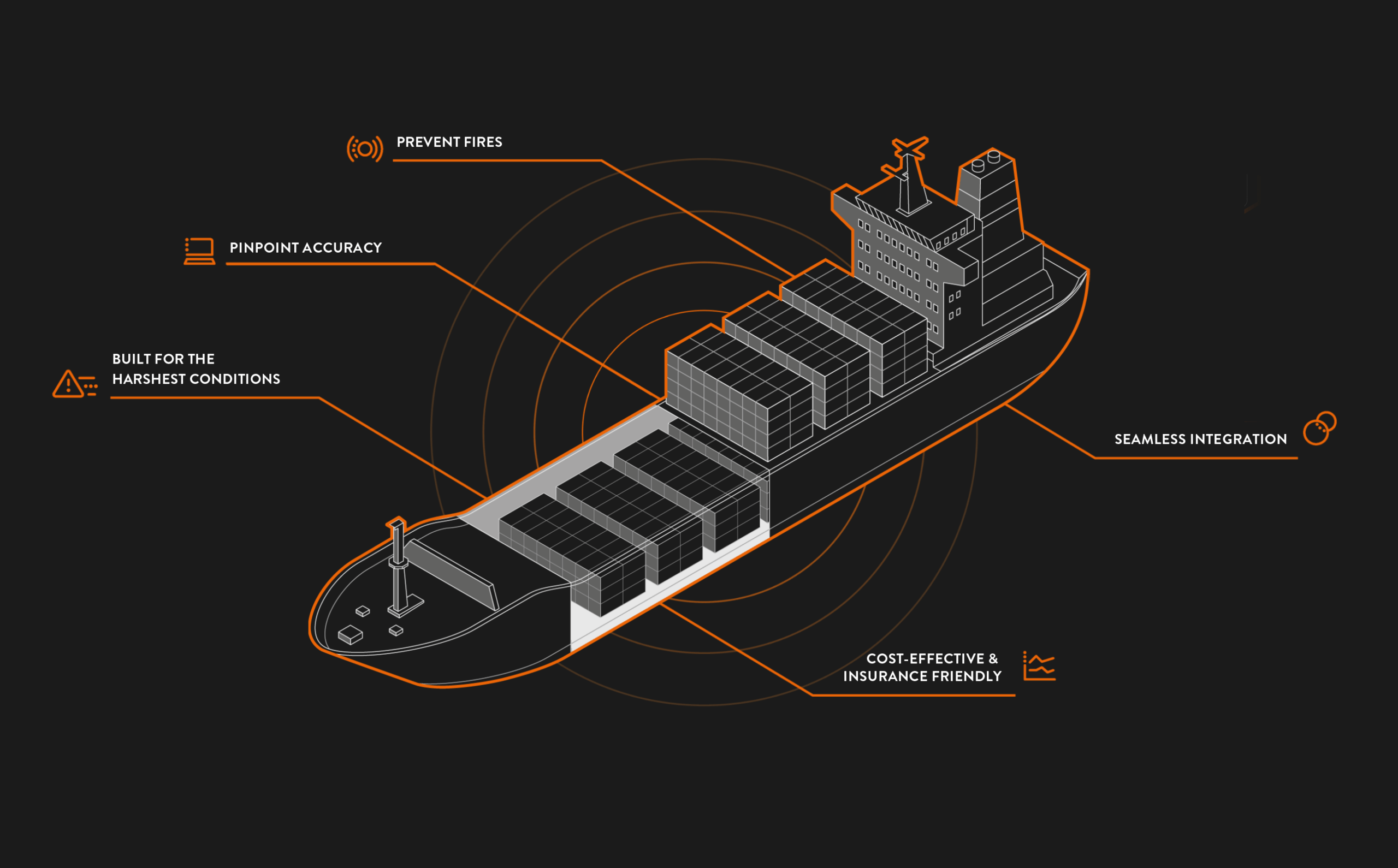

PREVENT FIRES BEFORE THEY START

Detects temperature anomalies at ambient levels before they become critical.

PINPOINT ACCURACY

Real-time localization of temperature events within containers.

BUILT FOR HARSH CONDITIONS

Durable, marine-grade components ensure long-term reliability.

SEAMLESS INTEGRATION

Minimal maintenance, global 24/7 support and seamless integration with the safety management system.

COST-EFFECTIVE & INSURANCE FRIENDLY

Reduce fire risks, lower insurance costs, and enhance safety compliance.

Reaching where others can’t

– how the Temperature Monitoring System (TMS) works

A Smart Sensor Network

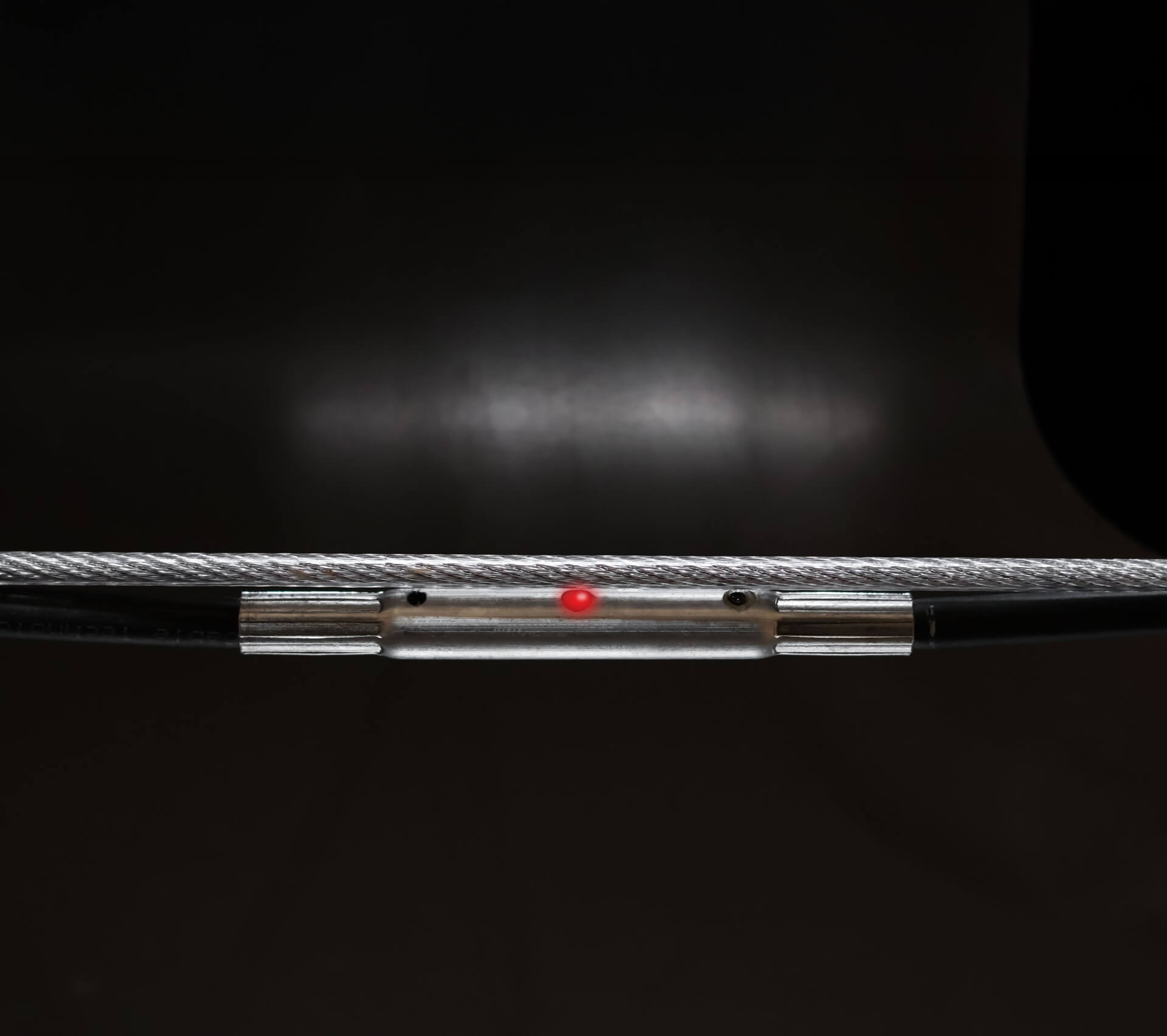

At the heart of the TMS-system is a digital linear sensor network, designed to run along the container stacks. It features “Computer-in-Cable” technology – where sensors continuously collect and process temperature data in real time.

Built for Extreme Maritime Conditions

Developed for marine applications and large-scale industrial infrastructure, the Temperature Monitoring System is engineered for harsh environments like salt, heat, motion, and vibration. It reliably detects minimal thermal anomalies – even at ambient temperatures, before a fire starts.

Modular & Repairable by Design

The TMS is installed in shorter segments rather than one continuous cable — making setup faster and easier. Each segment maps directly to a container. In case of a fault, only the affected segment needs replacing, simplifying maintenance and repair.

Integrate SMiG with all safety-related systems